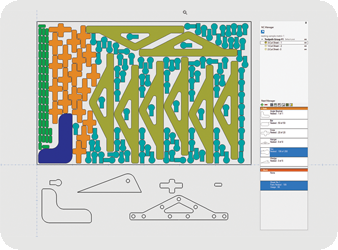

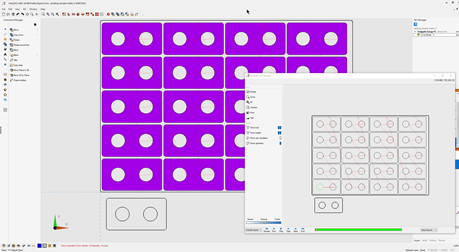

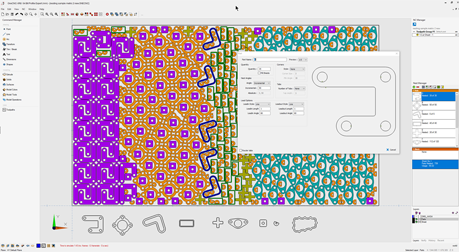

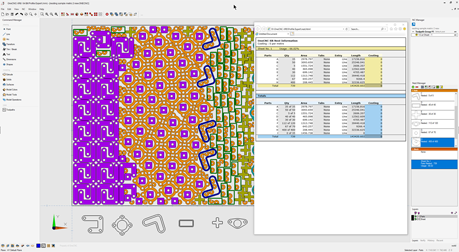

OneCNC CAD / CAM Profiler er en komplet enkeltstående design- og fremstillingsløsning. Dette inkluderer komplet CAD integreret med CAM for at skabe dele til klipning.

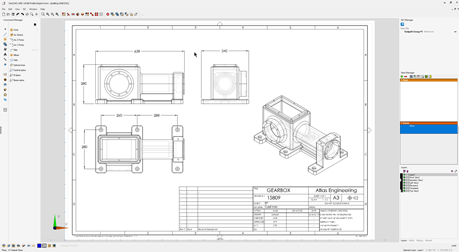

OneCNC Profiler har en unik kombination af geometri-konstruktion og afhængigt af versionen har hybride modelleringsværktøjer, der giver dig mulighed for at oprette detaljerede, nøjagtige 3D-modeller af selv de mest komplekse mekaniske dele enkelt og effektivt.